|

Installing Wall in Place

Before you nail up the plates,

mark the locations for the studs. Studs are normally placed 16", on center,

apart. Either make the mark on the edge of the plates at 16" or make you marks

on the top of the studs 15 3/4" apart (mark in front of where the stud

goes).

After you have determined how

to affix the top plate, go ahead and nail it into place. Use 16d nails. Place

at least one nail every couple of feet. Tack the sole plate in place by not

completely driving a nail near each end of the plate.

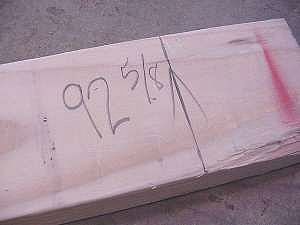

Measure from the bottom of the

top plate to the top of the sole plate. Add 3/16" to this measurement. This is

how long the studs need to be. Cut one stud to length and put it in place. You

will likely have to put the stud in diagonally and tap it into place. Using a

level, check to make sure the wall is plumb. If not, loosen the sole plate and

tap it into place. Make sure you make identical adjustments to the entire sole

plate. Check your measurement to the facing wall. Once the wall is plumb, go

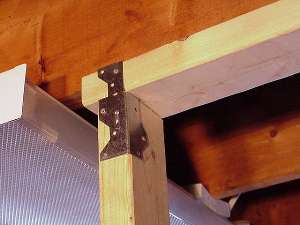

ahead and toe-nail the stud top and bottom. You toe-nail by holding the nail

(16d nails for this) at a 45 degree angle about 2 inches up the board and

nailing down through the stud into the plate. Alternatively, you can use a

nailing plate with smaller nails (picture down below) Cut the other studs to

the same dimension and toe-nail them into place every 16", on

center.

|

|