|

Sanding the Floor

After you have selected the sander that you want to

use, it is time to put on the sandpaper and get to work. Always keep in mind

that the objective is to remove as little wood as possible to get the job

done.

Picking the Sandpaper

In general, you are going to start with a coarse-grit

sandpaper and work your way up to a finer-grit sandpaper for the final sanding.

A good rule of thumb is to start with as fine a paper as will get the job

done. An easy way to determine the right grit is to test a small,

inconspicuous patch with a fine or medium grit paper. Generally 60 or 80. If

the paper is taking up the appropriate amount of material, keep using it. If

that particular grit isn't cutting enough or if the paper becomes clogged then

you should move down a grade. When moving between grits, it is a VERY good idea

to vacuum the floor.

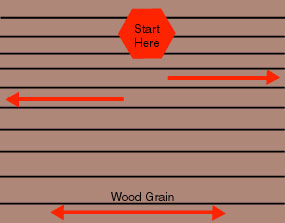

Sanding the floor with a DRUM sander

When sanding with a drum sander, only sand to within

4-6 inches of the wall. Start in the middle of the room and sand one half at a

time (see diagram). On most drum sanders there is a lever that lowers the drum

onto the surface to be sanded. While slowly moving the sander forward, gently

lower the drum against the floor. Keep the sander moving forward,

sanding WITH the grain. As you approach the end of the floor, work the lever to

lift the drum from the floor. Pull the sander back to the center of the floor

and position the sander so that the second pass will overlap the second pass by

a couple of inches. Continue to make passes until you finish up one half and

then move to the other half.

Sanding the floor with a PLATFORM sander

The method for sanding the floor with a platform

(pad) sander is the same as the drum sander. The platform sander tends to

"float" over the surface but continue to push the sander along with the grain of

the wood. A platform sander will also allow you to get closer to the

edges.

Sanding the Edges

You can sand the edges with an edging sander or a

small random orbital sander. An edging sander will likely be faster. Make sure

that you sand down to the same level that the big sander left.

|