|

Cutting the Pieces

For the next step, you must

install the cap molding. For the first wall, cut the molding to length and nail

it to the 1x4 and, depending on how straight the wall is, to the wall. Assuming

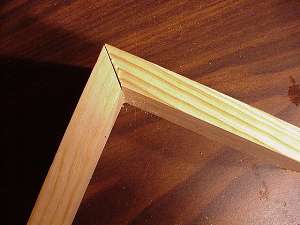

the first corner is an inside one (first picture), the first cut on the second

wall is made at a 45 degree angle. Make the cut so that it slopes toward the

middle of the front. Using a coping saw, cut perpendicular to the face of the

cap molding along the line between the angle and the face (see picture). Once

this joint is good, cut the other end (square) to length and nail the cap

molding in place. If the corners are outside corners, miter the ends at 45

degrees. Continue around the room using the same procedure. Small finishing

nails, about 4 penny are good for this. Make sure that you set all of the

nails.

Now is a good time to fill in

the nail holes and cracks. If the molding is to be painted, I generally use

latex painters caulk to fill the cracks between the molding and the wall and

putty to fill the nail holes. In a pinch, you can also use the caulk to fill in

the nail holes. After you have the caulk in place, run a damp sponge along the

joint to smooth/remove the caulk.

If you are using a clear

finish on the shoe or quarter-round, now is the time to paint the molding

already on the wall. I generally mask off the wall and paint the molding with

an interior latex semi-gloss paint. Whatever you use, make sure that is

compatible with the primer you used.

While the paint is drying, go

ahead and stain/finish the shoe molding. I generally use a "natural" shade

oil-based stain followed by a coat of oil-based polyurethane. If you are trying

to match existing molding, you may have to experiment on a small piece to get

the color right. After the finish is dry, nail the shoe molding in place. Use

a small (I prefer 1 1/2" 4 penny) finishing nail. If you are using hardwood,

you may have to drill holes in the molding so that you do not split the wood.

Drill holes that are just a bit smaller than the nail.

|

|